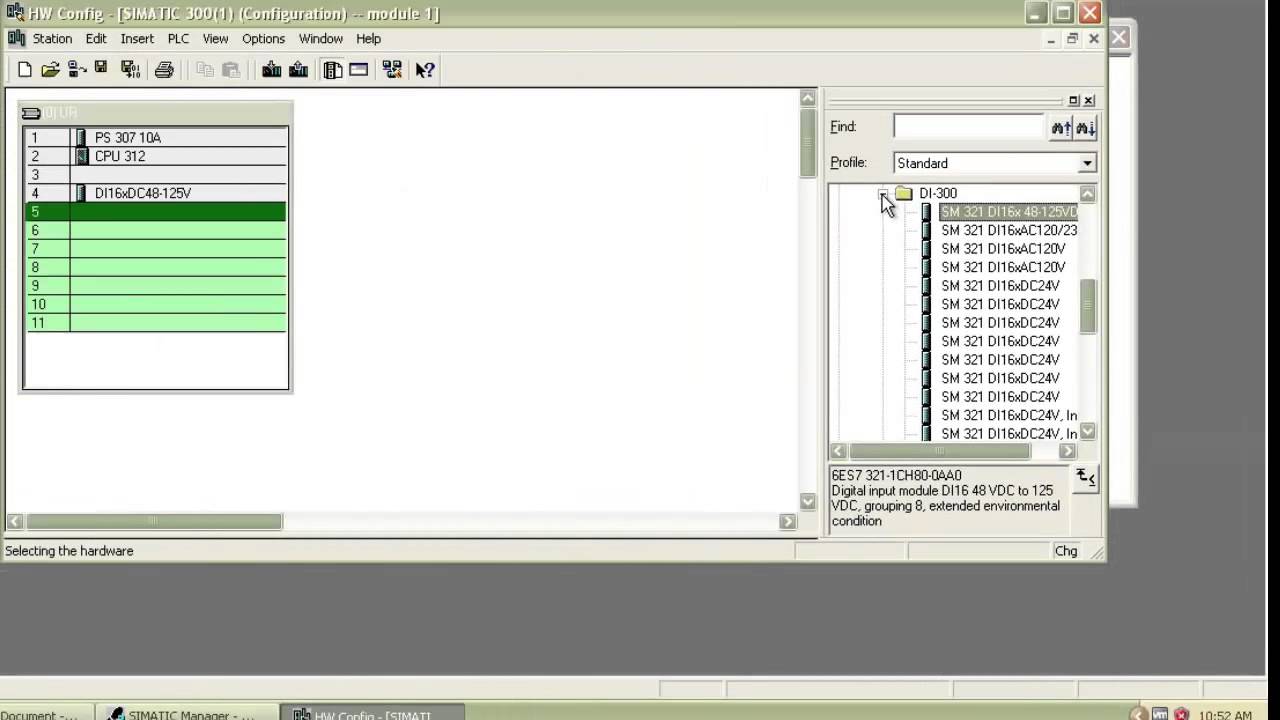

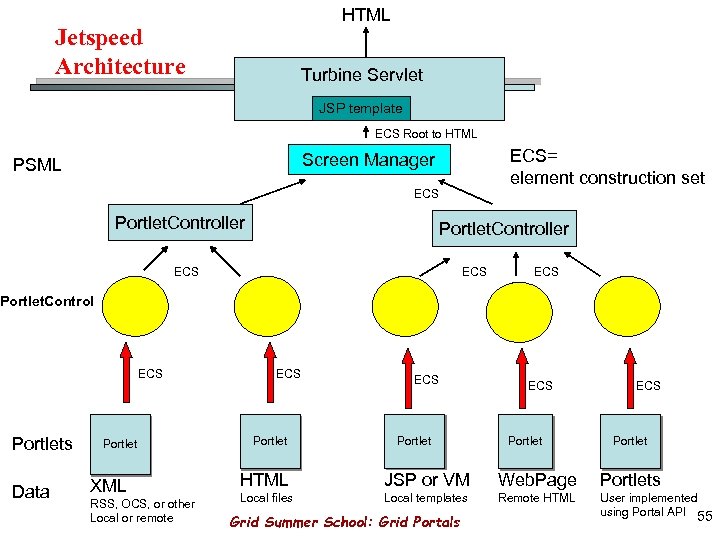

Password protection and different access privileges.The reports can be saved in the ASM or exported for further use.ĪSM provides all typical SCADA functions, for example: The module permits analysis of current and historical data in selectable time periods for documentation of the performance of individual analyzers up to the complete plant using the reporting module. This is a comprehensive function for producing customized reports. The view of key performance indicators (KPI) provides a fast overview of the analyzer's performance such as availability, error rate and maintenance frequency Documentation such as maintenance procedures or manuals can be opened to support the maintenance work. II, Siemens MicroSAM, etc.).ĭevice-specific maintenance tasks can be specified here, their timing defined, and checked. This test can be started automatically at specific intervals or manually by the ASM.Ĭarries out a calibration on the analyzer and monitors the results (this module is only available for analyzers which support remote calibration, e.g. The current measured values are displayed in a table, historical values can be analyzed with the trend display using selectable time windows.Ĭhecking the reliability of the measured values of analyzers using various routines and methods. The current analyzer status, planned maintenance work, and configuration data are displayed. Provides a detailed overview of the selected analyzer. ASM is operated from a PCS 7 environment, and it is possible to navigate between overview screens, device-specific displays and general functions.ĪSM has the following function modules for each analyzer for performing operator control and monitoring tasks: Information of the analyzers is collected over the communications network and saved in the central ASM database for further analysis. ASM can be integrated in an existing Ethernet network.Siemens Scalance Ethernet switches for design of electrical and optical Industrial Ethernet in line and star structures design in ring structures is possible to increase the fail-safety of the network.Data exchange with other systems possible using OPC.Analyzes without a communication interface can be integrated by connecting the signals to Siemens SIMATIC components.Integration of analyzers using PROFINET, ModbusTCP or OPC data exchange.

0 kommentar(er)

0 kommentar(er)